Welcome customers to come for consultation, negotiation, and business cooperation!

+86-189 2535 4376 (Manager Liao)

+86-189 2535 4376 (Manager Liao)

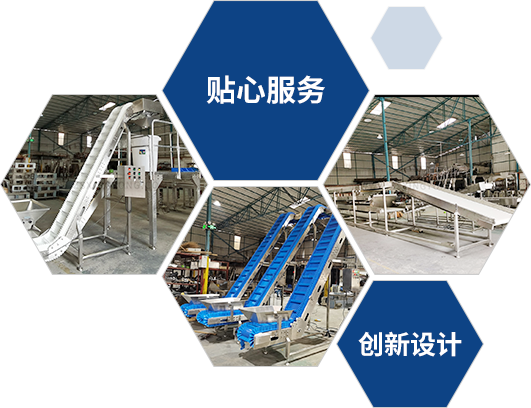

With the rapid development of the packaging industry at home and abroad and the continuous improvement of the degree of automation, the entire market has also put forward new requirements for the auxiliary equipment of packaging machinery High speed operation, long term stability, hydrogene level and humanized design will come a new trend; The intelligent acquiring equipment developed and produced by Zhongshan Xingyong Machinery Co., Ltd. is closed to the market demand, combined with the new market trend and years of technical experience, committed to the actual situation of domestic and foreign agents and large, medium and small manufacturers, saving customers money, effort and word; According to the actual transportation demand of customer materials, specifically customize the transportation equipment production line; It provides a low cost and high efficiency labor saving and even unmanned production and automatic production scheme

2006Year

The company was founded

30+

Automatic processing equipment

20+

The products are sold all over the world

2000+

Serving many customers

Relying on abundant resources and talents, equipped with experienced mechanical team members, facing the market demand of mechanization

Capable of undertaking product supply, technical support and service of the project

The company has been awarded as Guangdong High tech Enterprise, Zhongshan Science and Technology Innovation Enterprise, etc

It is committed to saving money, effort and word for domestic and foreign agents and large, medium and small manufacturers

It provides low cost, cost effective and even unmanned production, automated production solutions

Have considered services, interactive strategies, and one to one communication with customers

Establish an emergency maintenance service team to meet your needs with diversified products and professional production Each project has a dedicated engineer in charge

Solve all types of problems, do a good job in every product detail, and show it to customers

Online customer service quickly responds to your problems, and special personnel are responsible for following up, so that after sales service is free of worries

03

2023-08

What are the benefits that food-grade conveyor belts can bring to food factories

13

2023-07

Title Innovative technology improves food delivery equipment and enhances food safety and quality assurance

11

2023-07

High-efficiency automatic potato chip packaging machine to improve production efficiency and packaging quality

28

2023-02

Analysis of the control of the belt conveyor to the conveying system